Written by: Nicole Lau

Photography by: Elisa Deljanin Padula

Richard Korenstein

Richard Korenstein never wanted a company that would require him to stand on a corner and say, “I have a hundred buttons today, come and buy them now.” So when he founded R. Kaye in 1991, he focused on providing customized pieces for the garment sector trade, stocking thousands of different styles and letting customers choose what they want.

For the first 21 years in business, R. Kaye made custom buttons, dye to match buttons, covered buttons, and casted metal buttons, which are widely used by the military, in addition to some novelty trims, zipper pulls, closures, and buckles. Four years ago, they opened a custom jewelry division which allowed clients to cross reference items from the button line and convert them to jewelry pieces. A belt buckle became a shoe buckle and a covered button became earrings.

TURNING IDEAS TO CREATIONS

The terminology for what Richard does is a jobber. He determines the design and material of the product with the client then enlists the services of factories across the U.S. and oversees the entire production process. He contracts casting factories in the New England area, plastic factories in the Midwest, and dyeing plants and covered button factories in the New York City region.

To showcase all that they can do, Richard encourages customers to spend a day at the studio searching through the mold books and picking out pieces that would create what they are looking for. In a week or less, the pieces will arrive from the factories and R. Kaye’s team of four employees will solder and assemble the pieces in-house. Sometimes clients bring in 3D sketches with specs for the mold maker to hand craft, or physical products made on a 3D printer which are sunk into a mold to replicate then customized to their specifications.

In theory, R. Kaye is a small boutique. They work with the small-end client to explain how they can create the product they envision based on what is attainable for the factories and feasible for the customer.

“Most of the time a customer sitting in front of me is getting beaten down that they can’t do it or it doesn’t exist,” says Richard. “It is not that we can’t do it, I’m going to show them how to do it, whether it is casted metal, plated finish, with enamel color, or rhinestones that go in it. It’s very reassuring for a designer to not walk away and say, ‘Now where do I have to look?’ They just have to make a decision based on what I explained on how we can create it.”

GARMENT DISTRICT EDUCATED

How Richard comes up with the solution to challenging design project is hard for him to explain because “a lot of things I just know,” he says. “There are things and steps that are just burned into me from all the years of doing everything.”

Richard has been working in the Garment District since 1978. His parents owned a bridge club and one of the players had a friend who needed help in his office. So at the age of 20, he became an office assistant for an evening wear jewelry company.

“I would tackle any job whether it was hand counting buttons, or inspecting deliveries to accounts, or helping the salesmen when they were on vacation,” says Richard. “I really learned every aspect of the business.”

Although Richard had gone to school for Hotel and Restaurant management, it was not a difficult transition because he had good customer service skills and an aptitude for wood/metal shop in high school. After almost 10 years at the company, he left and proceeded to three more different companies.

“I kept showing all the companies I had worked for the right routine and mechanisms of how to create something,” says Richard. “It got to point where I was tired of educating everybody in my wake so I decided it was important to open my own company. I had two new young children in the house, a brand new home I just bought, and it was time to really solidify myself.”

KEEPING IT 'MADE IN USA'

When R. Kaye acquired the custom jewelry division, it was exciting for them because it expanded their custom-made business and the additional revenue stream kept their domestic factories up and running.

R. Kaye won’t take fifty or a hundred gross orders of a plastic blouse button. Instead, they will take 100 to 500 piece novelty type items that the overseas factories don’t want to handle because the order is too small for them. “It’s like we are willing to run around for small tickets, which we’ll have plenty of at a given time,” explains Richard. Being able to custom-make products with no true minimums was very attractable and attainable for the accounts that would walk in the door.

In 1991 when R. Kaye opened for business, there wasn’t a considerable off-shoring effect. But by the late 1990s to 2000s, overseas factories were mass producing in full-packages, supplying the buttons and the fabric and exporting complete garments. As a result, many domestic businesses were hurting as their profit margins declined. Of the button companies in New York City’s Garment District, Richard estimates there used to be between 30 to 40. Today there are about 10. Even though R. Kaye’s custom buttons catered to the domestic market, the acquisition of the custom jewelry division took the pressure off trying to sell a button that nobody was prepared to buy.

The factories R. Kaye works with across the U.S. are used to manufacturing 25 to 50 gross of different quantity amounts. Now, they are making more smaller quantity orders. The factories are working a little harder but they are still in business with the same personal working for them.

In the studio, there is a technician who works on the cutting, manipulating, and soldering and two pasters who have expertise in how an earring gets glued as opposed to how a button gets glued.

R. Kaye has been at 545 8th Ave for the past 25 years but was faced with the decision of having to relocate last year after his 10 year lease expired. The building management gave Richard a new dollar amount which was a substantial increase.

Richard began searching in Brooklyn, Long Island City in Queens, and the Bronx for alternatives but ultimately decided to refocus back on his building despite the high rent increase. The determining factor was the tradeoff between moderately lower rent prices in other boroughs and accessibility for his customers to travel to his studio if he were to relocate outside of midtown Manhattan.

“When everybody gets off of Penn Station, or the Port Authority, or Grand Central, they are here. Will they travel that extra commute?” asks Richard. “I was willing to think about it but at the end of the day, it didn’t seem practical to do that.”

To offset the increase in expense, Richard consolidated his business and gave his neighbor 20% of his space. A designer rents out a small section of his office where she designs her patterns and sends out garments to be cut and sewn in the factories down the block.

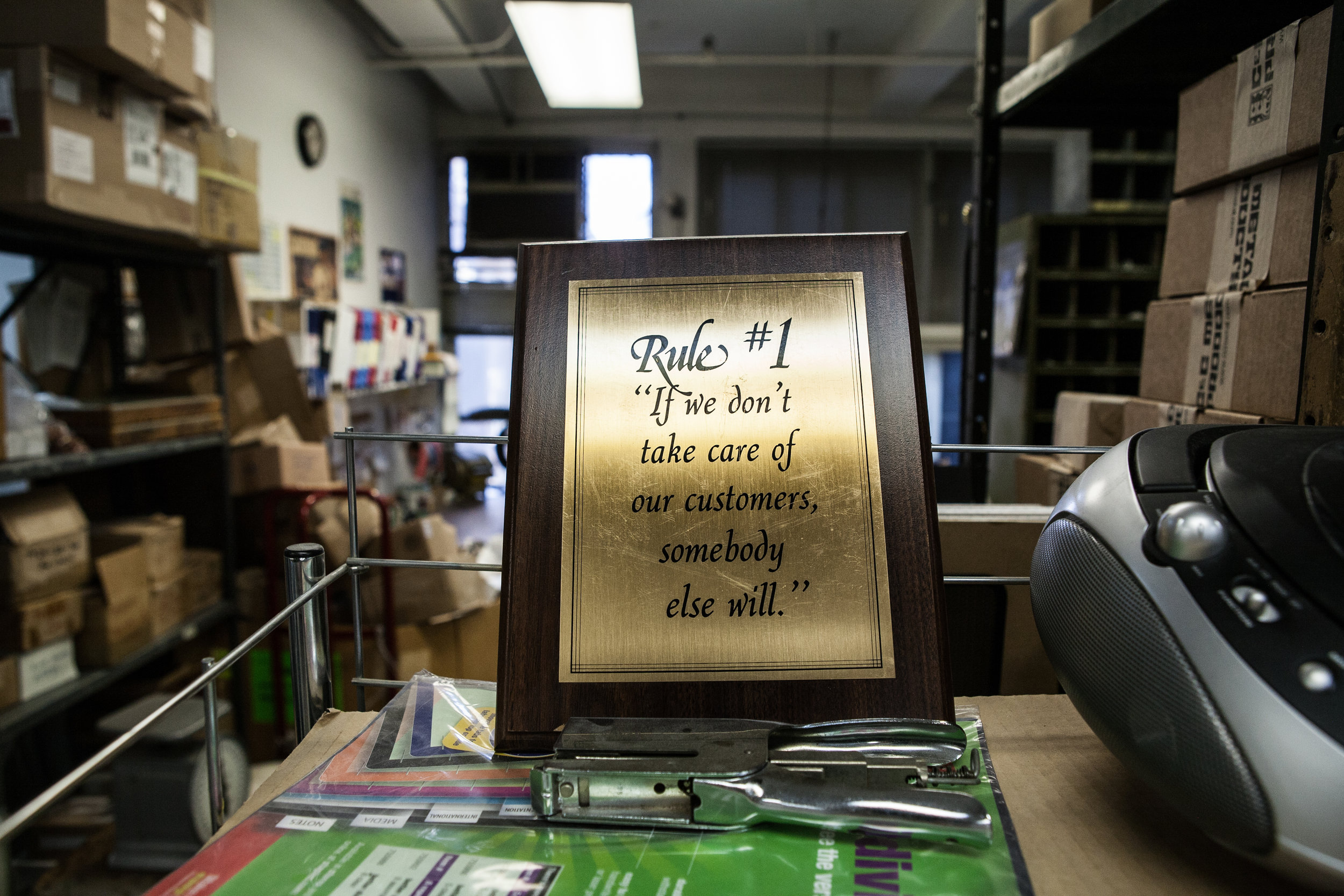

For Richard, it always comes down to his customers.

“While they may not know it when they first meet me, when they see the product that has been created, they are coming back for the next project to do,” says Richard.

For every customer that walks in his door, Richard instinctively asks, “Are they happy with the product? Are they paying a fair amount and getting what they paid for?” The customer is always first.